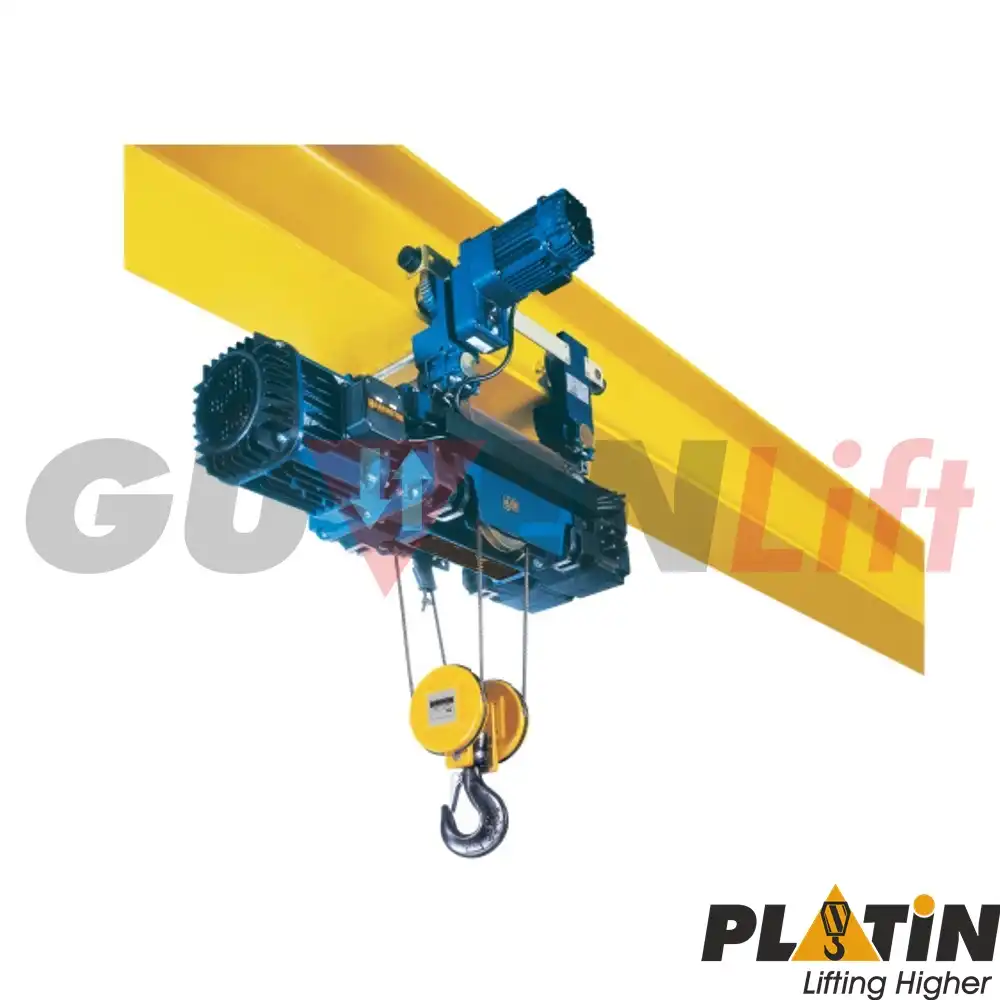

A wire rope hoist is a type of lifting device that utilizes a wire rope and a drum to lift and move heavy loads in industrial and commercial settings. It is commonly used in construction sites, manufacturing facilities, warehouses, and other environments where materials need to be lifted and transported efficiently and safely.

Wire Rope: The wire rope is a critical component of a wire rope hoist. It consists of multiple strands of steel wires wound together to form a strong and durable lifting cable. The wire rope is designed to withstand heavy loads and provide the necessary strength and stability for lifting operations.

Drum: The drum is a cylindrical component around which the wire rope is wound. It is connected to a motor or gearbox system that enables the rotation of the drum. As the drum rotates, the wire rope is wound or unwound, allowing for the lifting or lowering of loads.

Hoist Motor: The hoist motor is responsible for providing the power to lift and move the loads. It is typically an electric motor that drives the rotation of the drum. The motor is designed to deliver sufficient power to handle the weight capacity of the hoist.

Control System: Wire rope hoists are equipped with control systems that allow operators to control the lifting, lowering, and movement of loads. These systems can include push-button pendant controls or remote control devices, providing ease of operation and precise load positioning.

High Lifting Capacity: Wire rope hoists are capable of lifting heavy loads, often ranging from a few hundred kilograms to several tons. The robust construction of the wire rope and the drum, along with the powerful hoist motor, enable efficient handling of substantial weights.

Versatility: Wire rope hoists are versatile and can be used in various applications. They can be customized with different lifting attachments such as hooks, slings, or specialized lifting devices to accommodate specific load requirements.

Precise Load Control: The design of wire rope hoists allows for precise control over the lifting and lowering of loads. The variable speed control and smooth operation ensure accurate positioning, making them suitable for applications that demand precision and delicate handling.

Durability and Reliability: Wire rope hoists are built to withstand demanding environments and continuous use. The steel wire rope is highly durable and resistant to wear, providing a long service life. Additionally, the hoist motor and control systems are designed for reliability and consistent performance.

Construction: Wire rope hoists are commonly used in construction sites for lifting and moving materials such as steel beams, concrete blocks, and construction equipment.

Manufacturing: In manufacturing facilities, wire rope hoists are employed for tasks like lifting heavy machinery components, loading and unloading goods, and moving materials along assembly lines.

Warehousing and Logistics: Wire rope hoists are utilized in warehouses and logistics centers for efficient loading and unloading of goods, organizing storage spaces, and transporting heavy items within the facility.

Shipbuilding and Ports: Wire rope hoists are essential in shipbuilding yards and ports for lifting and moving ship components, containers, and cargo.

When it comes to selling a Turkish wire rope hoist with a CE declaration, there are several important steps to follow. Here's a brief overview of the process:

Compliance with CE Standards: Ensure that the wire rope hoist you intend to sell meets the essential health, safety, and environmental requirements set forth by the European Union (EU) for CE certification. This includes adherence to relevant EU directives and standards specific to wire rope hoists.

CE Declaration of Conformity: Prepare a CE Declaration of Conformity for the wire rope hoist. This document states that the product complies with all applicable EU directives and standards. The declaration should include detailed information about the product, its intended use, and the conformity assessment procedure carried out.

Product Testing and Certification: Conduct necessary product testing to ensure compliance with EU standards. This may involve testing the hoist's electrical safety, mechanical performance, and any other relevant requirements. Engage a reputable testing laboratory or certification body to verify the product's conformity.

Technical Documentation: Compile comprehensive technical documentation that demonstrates the hoist's compliance with the applicable EU directives and standards. This documentation should include technical specifications, design drawings, user manuals, risk assessments, and test reports.

Authorized Representative: If you are a non-EU manufacturer, appoint an authorized representative located within the EU. This representative acts as a liaison between you and the EU authorities, ensuring compliance with regulatory requirements.

CE Marking: Once the wire rope hoist has been successfully tested and meets all relevant requirements, affix the CE marking to the product. The CE marking indicates that the hoist complies with EU standards and can be legally sold within the European Economic Area (EEA).

User Manual and Labeling: Prepare a comprehensive user manual that provides clear instructions for safe installation, operation, and maintenance of the wire rope hoist. Ensure that the product is appropriately labeled with important information such as the manufacturer's details, model number, serial number, and CE marking.

Distribution and Market Access: With the CE declaration and compliance in place, you can market and sell the Turkish wire rope hoist within the EEA countries. It's important to understand any specific national regulations or additional requirements that may apply in certain EU member states.

Remember that the process of obtaining CE certification and compliance can be complex. It's advisable to consult with experts in EU product compliance, such as certification bodies, legal advisors, or consultants with experience in CE marking for mechanical equipment, to ensure that you navigate the process correctly and meet all necessary requirements.

To buy a Turkish wire rope hoist from another country, you can follow these general steps:

Research and Identify Suppliers: Conduct thorough research to identify Turkish manufacturers or distributors that specialize in wire rope hoists. Utilize online platforms, industry directories, trade shows, and business networks to find potential suppliers. Ensure that the suppliers have a good reputation, experience, and offer high-quality products.

Contact Suppliers: Reach out to the selected suppliers and express your interest in purchasing their wire rope hoists. Provide them with detailed information about your requirements, including specifications, quantities, delivery timelines, and any customization or special requests.

Request Quotations: Ask the suppliers to provide you with detailed quotations for the wire rope hoists. The quotations should include the product specifications, pricing, payment terms, delivery options, and any applicable certifications or compliance details (such as CE certification).

Evaluate Quotations and Select a Supplier: Evaluate the received quotations based on factors such as pricing, product quality, reputation of the supplier, delivery terms, and after-sales support. Choose a supplier that meets your requirements and offers the best overall value for your investment.

Negotiate and Finalize the Purchase Agreement: Engage in negotiations with the selected supplier to finalize the purchase agreement. Pay attention to important aspects such as payment terms, delivery terms (including shipping arrangements), warranties, return policies, and any other specific terms and conditions.

Arrange Payment: Determine the payment method and make the necessary arrangements to complete the payment. Depending on the agreement, you may need to provide an initial deposit or arrange for a letter of credit to secure the transaction.

Shipping and Logistics: Coordinate with the supplier to arrange the shipping and logistics for the wire rope hoists. Determine the shipping method, transportation mode (air, sea, land), and any necessary customs clearance procedures. Ensure that all relevant documentation, such as invoices, packing lists, and certificates of origin, are prepared and provided by the supplier.

Receive and Inspect the Wire Rope Hoists: Once the shipment arrives in your country, receive and inspect the wire rope hoists to ensure they meet your specifications and quality expectations. Check for any damages during transit and verify that all necessary documentation is in order.

Installation and After-Sales Support: Coordinate with the supplier or engage a local technician to install the wire rope hoists properly. If any issues or concerns arise, communicate with the supplier to seek resolution and take advantage of any warranties or after-sales support services they offer.

Ongoing Relationship: Maintain a good relationship with the supplier for any future requirements, spare parts, or technical assistance you may need.

Note: It's crucial to consider any import regulations, customs duties, taxes, and compliance requirements of your country when importing wire rope hoists. Ensure that you adhere to all applicable legal and regulatory obligations to facilitate a smooth and compliant purchase process. Consulting with a freight forwarder, customs agent, or legal advisor experienced in international trade can be beneficial.

Copyright ©2022 Platin Vinç ve Vinç Ekipmanları